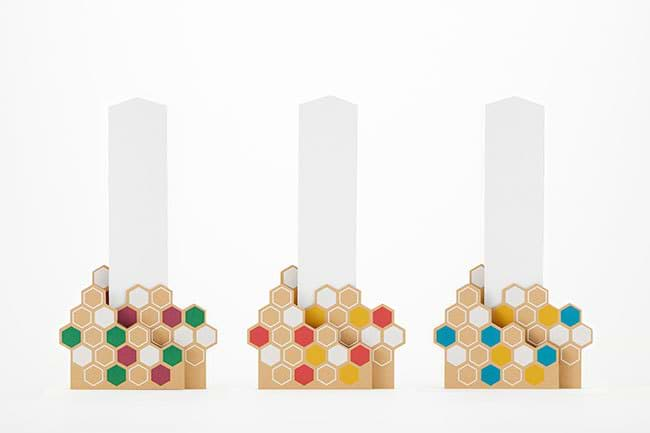

Following the first phase of Dentsu’s intellectual property (IP) monetization initiative, cardboard manufacturer Tachibana Ltd. purchased the design license for, and the trademark rights to commercialize, a simple cardboard ofudana family shrine that a Dentsu employee had designed at the Product Design School 2017.

• Price: ¥1,150 (tax included)

• Production, sale: Tachibana Ltd

Cardboard Maker Buys Dentsu Design Rights

In Japanese homes and offices, one generally finds kamidana, family shrines to honor deceased ancestors and relatives. Prayers in envelopes (ofuda) are bought at Shinto shrines and placed in the kamidana.

Tachibana Ltd. President Masahiko Nohara, and Dentsu’s Yuko Katsumata, who created the ofudana, discuss the potential of the IP commercialization business model from the manufacturing and advertising industry perspectives.

The issues faced by the cardboard manufacturer and advertising agency respectably

| Katsumata: |

The cardboard ofudana has its beginnings in the Product Design School 2017. In this Dentsu-wide project, art directors, planners, and copywriters designed products to be made of cardboard. The items were displayed in the Dentsu Head Office last November and December. I believe that you read about the exhibition on the ”Dentsu-Ho”, Dentsu’s owned media website, where you noticed the ofudana I had designed. This led to Tachibana commercializing the product. |

| Nohara: | Tachibana is a maker and seller of paper, plastic, and cardboard products. We also handle general packaging, cushioning materials and stickers that go along with cardboard. |

| Katsumata: | Yes, and I believe Tachibana-founded in 1964-recently has been expanding. |

| Nohara: | Certainly. Since I became president about 10 years ago, we have been making efforts in the area of logistic processing. In this connection, we have even bought out factories specializing in food products. We now manufacture and sell teabags for black tea, as well as packaging and packaging workstation setups for cookies and chocolates. |

| Katsumata: | It is unusual that a cardboard manufacturer would handle food products. Why did you decided to branch out into something other than packaging? |

| Nohara: |

To the extent that cardboard is expected to be the same, no matter where it is bought, we receive complaints if it is not. This makes it difficult for us to differentiate ourselves and create added value. With a consumable such as cardboard, orders are pretty constant and cost competition steady. Any change in consumer purchasing behavior and the current rising cost of raw materials thus are a big issue in terms of creating added value. |

| Katsumata: | How did you come to focus on food wrappers and packaging? |

| Nohara: |

This came about as a result of Tachibana’s core business in cardboard and packing technologies and equipment. Originally, our business merely sold boxes. Then we added packaging workstation setups and marketed packed finished products, which became very successful. But what was it that led the Dentsu advertising agency to engage in the product design licensing? |

| Katsumata: |

When I began working at Dentsu, it had already perfected the kind of media transactions that are the mainstay of advertising agencies. However, as consumer behavior changed and client advertising needs diversified, Dentsu also had to change. Thus, it was decided that Dentsu would leverage its strengths to develop business in a new area. One of the businesses created by leveraging our strengths as an advertising agency involves monetizing IP utilizing product design and trademark rights. |

| Nohara: |

I see. In terms of business development, Tachibana also took on the challenge of creating a B2C business by making original Tachibana brand teabags on the occasion of our 50th anniversary. For this, we utilized the equipment and knowledge of tea-making we had gained through our OEM business involving other brands. We sold the tea online, and decided to use this channel to create other B2C products, which is how we discovered the ofudana. |

The Value of Disposability

| Katsumata: | As Tachibana is a professional in the cardboard industry, what was your impression when you saw the Product Design School 2017 exhibition? |

| Nohara: |

I was shocked, but in a good way. Always thinking about added value and differentiation, and wanting to develop products in house that only a cardboard company can create, I was stymied by my lack of concrete ideas. Your exhibition provided us with an abundance of hints about what we had only vaguely considered. More than anything, I was impressed by the fact that cardboard had been used in a design for everyday items. And I was reminded that our ideas and perspectives had been rooted in cardboard solely as a packaging material. |

| Katsumata: | Among all the different products on display at that exhibit, why did you decide to commercialize the ofudana? |

| Nohara: |

As soon as I saw the ofudana I thought it was interesting, and immediately envisioned the blueprint in my mind. Right away, I knew mass production was possible. However, it wouldn’t be interesting to simply make ofudana using a machine. Were we to make them, we had to incorporate our manufacturing expertise. Also, by coincidence I had heard that ofuda holders made from wood were selling at a souvenir shop in Asakusa where our offices are located, which I thought was very interesting. Speaking of which, how did the idea of using cardboard to make an ofuda holder come about? |

| Katsumata: |

Cardboard is something that gets thrown away after it is used, right? In light of this disposability, I wondered if there wasn’t some way to increase the value of cardboard itself. Thinking about small problems in my life, I recalled the ofuda that I buy every time I go to a shrine, although at home I have no kamidana in which to put it. I just place the ofuda on a bookshelf-which has always bothered me-and, once a year, return it to the shrine to dispose of it according to Shinto custom. Were the ofuda holder made of cardboard, I would be able to dispose of both items at the shrine. |

| Nohara: | Since the idea came from an experience in your own life, you may have assumed other people were in a similar situation. |

| Katsumata: |

Magazines regularly have special features focused on visiting Shinto shrines and, for many Japanese, shrines and ofuda are very important. But, depending on the conditions in one’s home, making a kamidana might be a bit of a challenge, as it was in my case. I thought it would be nice if the ofudana could convey a sense of living with a kamidana, albeit in a slightly unconventional way. As president of Tachibana, what is your vision for developing ofudana as a product? |

| Nohara: | I believe there are a variety of possibilities, as the product has appeal for an array of sales channels, including souvenir shops near shrines, as well as shops selling items related to Buddhism. How did you imagine this product would be purchased? |

| Katsumata: |

Of course, I thought it would be best if ofudana were handed out by shrine maidens when ofuda are purchased at a shrine. I want them given to people who want to enshrine the ofuda but have no kamidana in their homes. I designed them so that they easily might be incorporated into any purchaser’s lifestyle, as an element of interior design. Moreover, although they are meant to hold ofuda, they can also be used as a holder in which to keep post cards. |

| Nohara: | That’s true. I didn’t think of that during the design and prototype phases but, once I saw the finished product, I realized they would also be useful for holding restaurant business cards. |

| Katsumata: |

Perhaps, by making the kamidana from cardboard, I have eased the pressure some people may feel to buy a kamidana and maintain it properly. But that could be said not only of the ofudana; many other product ideas presented at the Product Design School 2017 exhibition obviate the need to buy their more traditional equivalents. |

| Nohara: | When I first saw ofudana, I was attracted to the quality of the design. Did you have much difficulty when creating it? |

| Katsumata: | I struggled with the drawings. I am a graphic designer, so my mind always focuses on two dimensions. But for this I had to create detailed drawings in order to acquire the design rights. |

| Nohara: | Others also may have struggled to make three-dimensional objects. Some of the exhibits were perhaps even a little crooked. |

| Katsumata: |

We cut the cardboard according to the drawings and tried to assemble our ideas, but sometimes that didn’t work. So, it would be back to the drawing board. That the whole process was repeated trial and error made me realize what product design is all about; there is a difference between what you imagine and what you are actually able to do with your hands. It was very difficult. |

Cardboard Offers Unlimited Possibilities

| Katsumata: | In the seven months since Dentsu’s lobby exhibition, you have already launched sales of the ofudana. Looking back, what do you believe are the benefits of having purchased for commercialization an advertising agency product idea? |

| Nohara: |

First of all, it was great to be able to play a role in developing into an actual product an idea that had originated with someone outside the cardboard industry. Further, when printing and processing cardboard, certain problems will often occur. So it was both rewarding and fun to have been able to propose ideas related to the processing technologies that are our area of expertise. It was also extremely stimulating for our employees, who seem eager for a chance to take on a challenge like this again. I am sure that the entire cardboard industry must feel the same way. |

| Katsumata: | Because we were able to create added value from a product that was not packaging, do you see any potential for B2C products made of cardboard? |

| Nohara: |

The advantages of cardboard are that it can be manufactured in small lots in a short time, it is easy to process, initial costs are low, and it can be recycled and custom-made to produce a variety of items. Seeing your ofudana and other Dentsu ideas made me feel that, while there are many areas in which cardboard could be used, there are few ideas emanating from the cardboard industry itself. This makes me certain that collaborative development of products is the best way to substantially expand possibilities. |

| Katsumata: |

Working with Tachibana on this project, I got a sense of your ability to make things quickly. Generally, our job is to sell ideas; we do not have a factory. However, working with people who do have a factory and make things gave me an idea of the speed with which things can be tried out and how ideas can take shape. I am thus convinced that there are possibilities for business focused on product design licensing. |

| Nohara: |

If ofudana sell well, perhaps this will motivate our employees to think they, too, can come up with ideas that similarly might succeed. The cardboard industry could utilize the materials, production technologies, and equipment it has used for making boxes to create something new. That could lead to the expansion of our entire industry. |

| Katsumata: | I am sure that the ofudana has also stimulated those of us working at Dentsu. As more employees find out this is something Dentsu can do, it should create an environment in which we will take on all kinds of challenges. |

Masahiko Nohara

President

Tachibana Ltd.

Yuko Katsumata

Art Director

Creative Planning Division 2